Applications

4-axis application

4-axis on NC rotary table

- Perfectly aligned with C-axis and repeatable accuracy

- Clamping - Milling - Swiveling - Milling

- DiaClamp® makes it possible

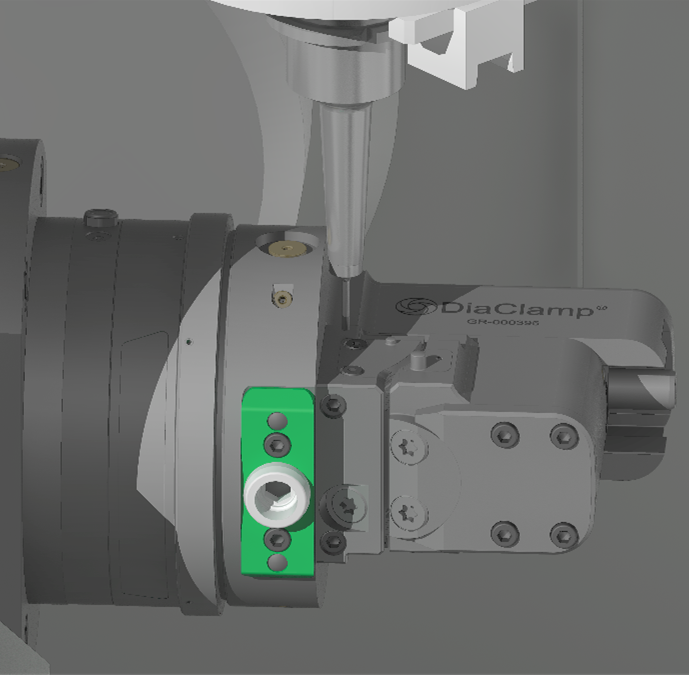

Photo DiaClamp® on a 4-axis

Rendering DiaClamp® on a 4-axis

Photo DiaClamp® on a 4-axis

5-axis application

5-axis

High freedom of movement for free and stable tool paths

Ideal clamping for tools with adjusted machining angles

Perfect clamping for demanding 5-axis simultaneous production

Workpiece clamping for highest surface quality

Photo DiaClamp® on a 5-axis

Rendering DiaClamp® on a 5-axis

Photo DiaClamp® on a 5-axis

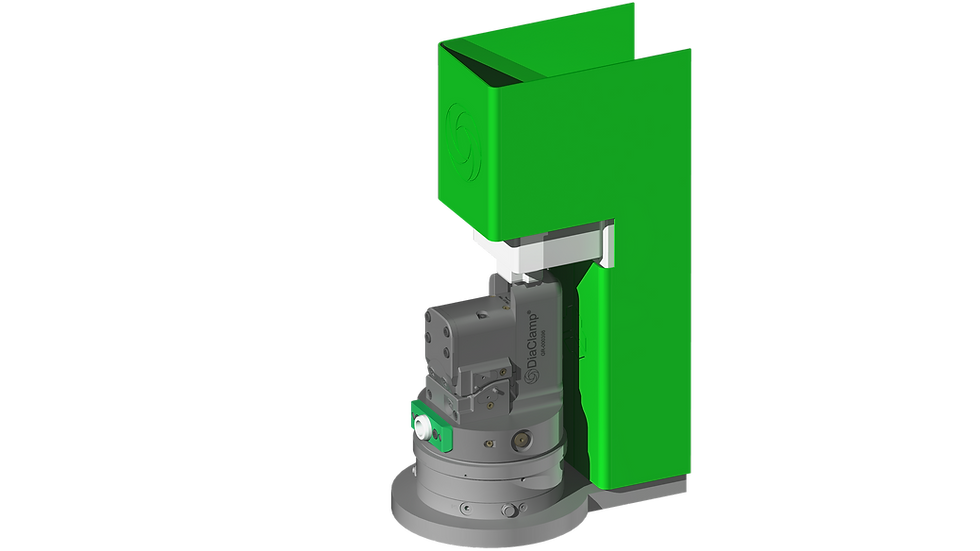

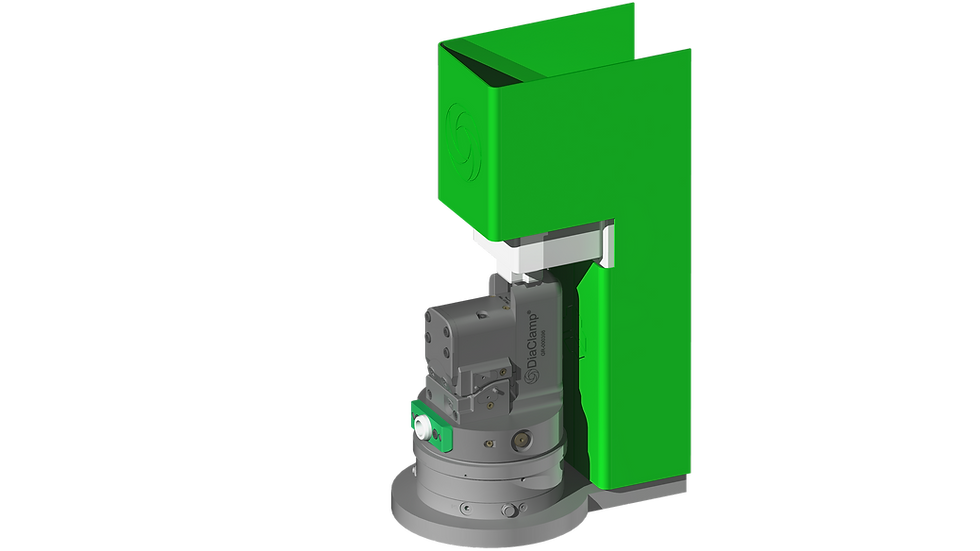

Workpiece loading station

Workpiece loading station

External workpiece loading for process-reliable fixation and continuous automation

External loading station for reproducible and collision-free transfer

External workpiece clamping solution supports efficiency and reduces setup times

Workpiece loading station for DiaClamp

Workpiece loading station for DiaClamp

Measuring probe

Best Fit

Reliable measurement on freeform surfaces

Automatic alignment and secure capture for best fit

Stable tension and precisely manufactured

DiaClamp on 3+1-axis CNC with BLUM Novotest measuring probe.

BLUM Novotest 3D Measuring Probe

DiaClamp on 3+1-axis CNC with BLUM Novotest measuring probe.

Milling

Milling tools

Low vibration, longer tool life

Secure hold, clean milling paths

Stable tension, perfect freeform surfaces

DiaClamp on 3+1-axis CNC during milling

DiaClamp on 3+1-axis CNC during milling

Automation

Workpiece handling system using robots

- Automatic loading of the DiaClamp® onto the loading station

- Automatic clamping according to preselected parameters: torque, travel speed, etc.

- Automatic transfer of the DiaClamp® to processing machines, precise, reliable, repeatable

WiCell with DiaLoad

WiCell with DiaLoad

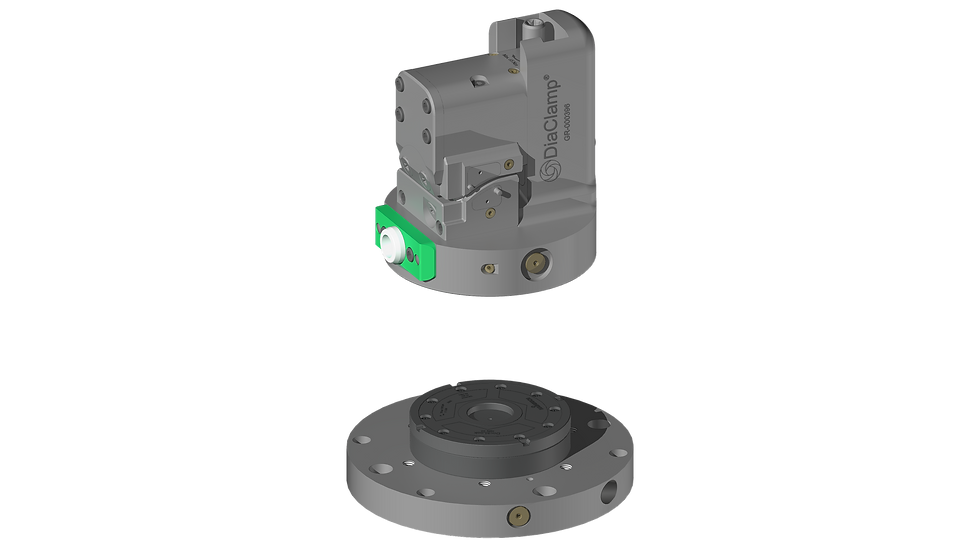

Palette interfaces

Pallet application

Zero-point clamping systems for flexibility

Quick and repeatable conversion

Reproducibly clamped in the machine

DiaClamp with PowerGrip Zero Point System

DiaClamp with DockLock Zero Point System

DiaClamp with MacroMagnum Zero Point System

DiaClamp with PowerGrip Zero Point System