News

January 2026

DiaClamp® – Successfully validated, precision meets innovation

In another customer project, we successfully validated the DiaClamp® workpiece clamping system under real production conditions for machining complex free-form surfaces.

The completed Site Acceptance Test (SAT) confirms: maximum clamping force, reproducible precision and comprehensive process reliability.

Technical highlights:

- Specially designed for challenging geometries such as blades and vanes

- Integrated zero point interface for minimal set-up times

- High repeat accuracy in 4- and 5-axis machining

Test results at a glance:

- Consistently high clamping force with varying contours

- No deformation of free-form surfaces

- Optimised accessibility for tool paths

DiaClamp® embodies Swiss precision and the courage to redefine boundaries. It opens up new possibilities for the demanding manufacture of complex components – reliable, innovative and perfect down to the last detail.

The DiaClamp® team in January 2026

DiaClamp® before machining on a 4th axis

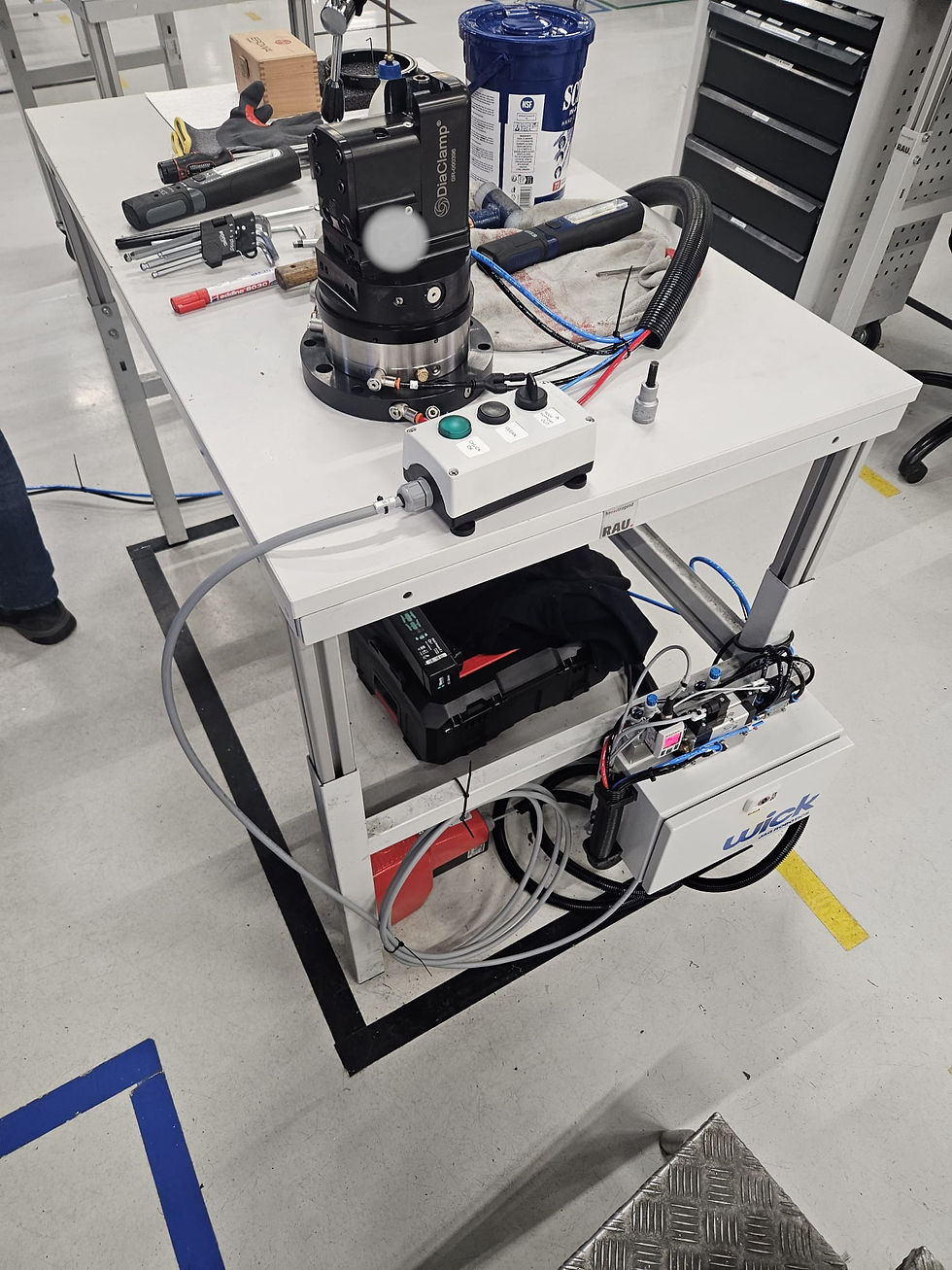

DiaClamp® on the preparation station

DiaClamp® during machining with the 4th axis

DiaClamp® before machining on a 4th axis

New Year 2025/2026

DiaClamp® – A year full of innovation and success

For DiaClamp®, 2025 was much more than just a successful year – it was a real milestone. With the further development of our workpiece clamping device for blades, vanes and complex free-form surfaces

in machining, we have not only optimised a product, but also set a new standard in manufacturing.

2025 was characterised by passion, vision, courage and shared successes.

We would like to express our sincere thanks to our customers, suppliers and business partners for their reliability, and especially to our outstanding team. Your trust, your ideas and your enthusiasm have made this success possible.

Now we are looking ahead: 2026 will be the year in which we redefine the boundaries of machining together with our customers, partners, suppliers and our team.

More precision. More efficiency. More possibilities. Thank you for your trust and shared passion.

We look forward to what lies ahead!

The DiaClamp team in the New Year 2025/2026

DiaClamp® on a 5-axis milling machine

DiaClamp® before machining on a 4th axis

DiaClamp® on 4th axis during machining

DiaClamp® on a 5-axis milling machine

December 2025

DiaClamp® - pronto per il SAT presso il cliente finale

Our innovative DiaClamp® workpiece clamping system was specially developed for the precise, reproducible machining of blades, vanes and other workpieces with complex free-form surfaces.

Technical highlights:

- Compatible with zero-point clamping systems for maximum process reliability

- High rigidity and repeatability for demanding geometries

- Optimised clamping force distribution for low-vibration machining processes

- Modular design for flexible adaptation to different workpiece shapes

- Digital twins for collision testing and CAM simulation

The FAT (Factory Acceptance Test) has been successfully completed. Installation with SAT (Site Acceptance Test) at the end customer's premises will follow next week.

This marks another important step on our path towards more efficient and digitally networked manufacturing processes.

A big thank you to our team and our end customers for the excellent cooperation.

The DiaClamp team in December 2025

DiaClamp® during milling on a 5-axis machine

DiaClamp® during milling on a 5-axis machine

November 2025

DiaClamp® - Another successful milestone

Our DiaClamp® workpiece clamping device has been tested again under real production conditions and has successfully met the demanding requirements for the manufacture of blades and vanes.

The special features at a glance:

- Precise zero point accuracy for complex manufacturing surfaces

- High repeatability with variable geometries

- Optimized clamping force distribution for sensitive components

With DiaClamp®, we are setting new standards in the manufacture of blades, vanes, and complex free-form geometries.

A big thank you to Albert, Hanspeter, and Philipp. Your commitment and expertise make all the difference—together, we are shaping the future of complex manufacturing.

The DiaClamp® team in Nov. 2025

Albert Ijspeert, Philipp Hugentobler und Hanspeter Müller (Von Links nach Rechts)

Das DiaClamp® Spannsystem ohne eingelegtes Blade

Hanspeter Müller mit dem DiaClamp® in der Hand.

Albert Ijspeert, Philipp Hugentobler und Hanspeter Müller (Von Links nach Rechts)

October 2025

DiaClamp® - Workpiece clamping devices for free-form surface machining in high-tech industries

The machining of complex free-form surfaces places the highest demands on precision, repeatability and process reliability, particularly in the aviation/space, energy and medical technology sectors as well as in optics manufacturing .

With the DiaClamp workpiece clamping system , we offer an innovative solution specifically developed for 4- and 5-axis machining .

Thanks to its modular design and high-precision clamping geometry, DiaClamp enables secure and distortion-free clamping even for delicate or difficult-to-access components . The clamping technology is designed for maximum accessibility for milling strategies with simultaneous multi-axis machining—a decisive advantage in the production of turbine blades, implants, optical components, or structural components made of high-performance materials.

Your benefits at a glance:

- Optimized for freeform surfaces and complex geometries

- High process reliability in 4-axis or 5-axis simultaneous machining

- Clamping force distribution without component deformation

- Repeatable positioning for series production

- Compatible with common zero-point clamping systems

DiaClamp developed and manufactured stands for Swiss precision, ready for the challenges of the future.

The DiaClamp® team in Oct. 2025

Rotating DiaClamp with anonymous blade

Rotating DiaClamp with anonymous blade

September 2025

DiaClamp® – Precision meets innovation in turbine manufacturing:

The production of blades and vanes for engines and stationary gas turbines places the highest demands on workpiece clamping : complex geometries, sensitive surfaces, tight tolerances, and often exotic materials such as titanium or Inconel. This is precisely where our new DiaClamp® clamping system comes into play.

What makes DiaClamp® special?

DiaClamp® was developed specifically for the requirements of turbine manufacturing – not as a compromise solution, but as a dedicated clamping device for these critical components.

The advantages at a glance:

- Even clamping force distribution – prevents deformation of thin-walled blades

- High repeatability – ideal for automated production cells

- Modularity & flexibility – for different blade and vane geometries

- Industry 4.0-ready – prepared for sensor technology and digital process integration

The DiaClamp® team in September 2025

An anonymised turbine blade

An anonymised turbine vane

An AI-generated turbine blade

An anonymised turbine blade